Corrosion protection and processing of magnet powders

Processing routes have been identified for the production of

complex shaped magnets. Possible routes have been narrowed

down to those deemed most promising. This includes two routes for

shaping the unsintered magnet, two binder systems for the magnet

production, and two coating systems for magnet raw material to

minimize oxygen and carbon uptake during processing. Testing of

subcomponents is progressing using substitute materials for NdFeB.

Thus stainless steel is utilised for testing binder systems and

pure iron is utilised for initial tests of protective coatings.

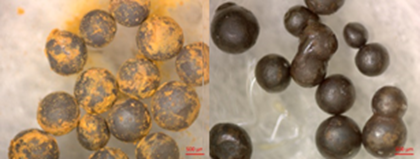

The photo shows iron shots protected by a coating compatible

with magnet production (right) together with unprotected iron shots

(left).

Contact: Martin Brorholt Sørensen, mbsn@teknologisk.dk, +45 7220

2099